OUR PRODUCTS

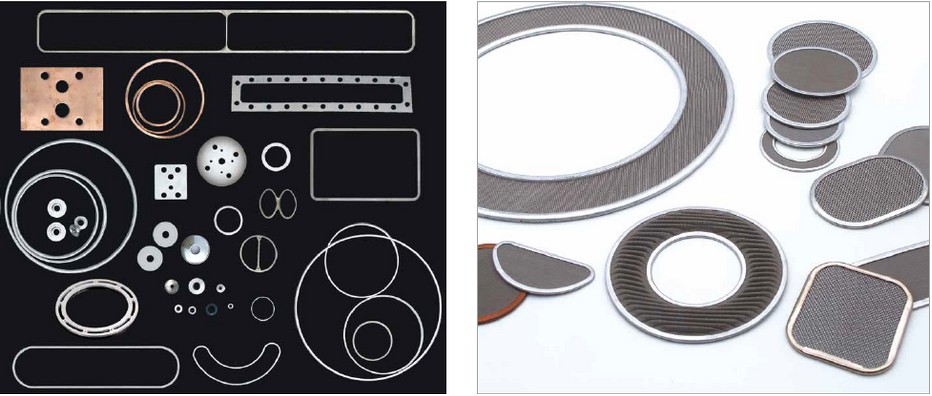

Die Cut Gaskets :

Product Description :

This is the most common and

widely used form of gasket. These are the gaskets cut/punched from sheets of different

materials. The same are regulalry used in pump, compressor, valve, textile, machinary,

blower, etc. industries. We used following methods for cutting/punching gaskets :

Piping Flange Gaskets :

Product Description :

This is a type of cut Gaskets.

But these gaskets are used between flanges and piping. These are used in large quantity

at Petro chemical Plants, Fertiliser, Refinaries, Chemical Plants, etc. These gaskets

are cut/punched from different material as per medium passing through pipe. These

gaskets follow different standard/class - ANSI, ASME, British, DIN, etc. - Here cutting

method is same as Die Cut Gaskets.

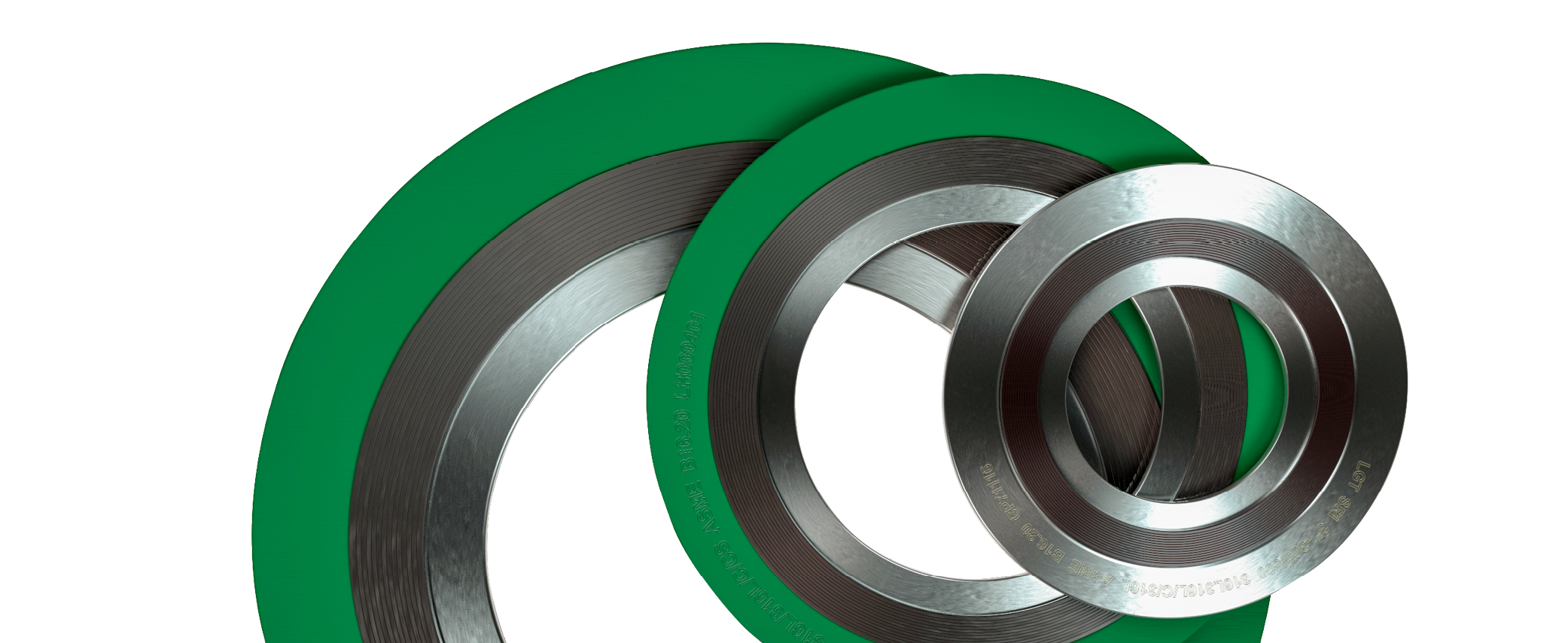

Spiral Wound Gaskets :

Product Description :

This is one type of

Piping/Flange Gasket. Where internal pressure & temprature is higher and thermal cycle

is more, SWG are used. They have good compressibilty and recovery. This give good leak

proof joint for more thermal cycle. They are also usd in HEat Exchanger and Valve

Industry.

As the name suggest, these are manufactured by evenly winding formed metal strip and

filler material over a die in concentric spiral manner. Usually formed metal strip is of

SS and filler material is Asbestos, Non Asbestos, PTFE, Pure Graphite, etc. Following

SWG are manufactured at SAGPL:

All Types of Wahers :

Product Description :

We manufacture all types of

metalic and non-metalic washers as per customer's requierment. We manufacture from 0.1mm

Thk. to 3mm Thk washers from deifferent material. We also manufactur

Copper-Asbestos or Copper-Non sbestos claded washers, widely used in power plants.

Metalic Gaskets :

Product Description :

These are soild ring gaskets

manufactured from diferent metals. They are used where internal pressure & temprature is

comparivly higher and thermal cycle is low. These are either punched from sheets or

machined on lathe/HMC. Gaskets with circular cross section are made from solid bar/wire.

Shrouded / Claded Gaskets :

Product Description :

These are special type of gaskets having very high compressibility and recovery. These

gaskets are jacketed Gaskets having on the metal layer with asbestos or non asbestos as

core / filler metallic. Mainly annealed copper or zinc plated steel is used for on the

layer.

POY / FDY Gaskets :

Product Description :

These are special gaskets for POY / FDY / Nylon industries. We manufactured following

types of gaskets for these industries:

These gaskets are manufactured from S.S or special Al. alloy.

Pealable Shims :

Product Description :

Peelable shims are a type of shim that can be easily adjusted by peeling off layers of

metal foil. This makes them ideal for applications where precise adjustments are

required, such as in the alignment of machinery or the balancing of rotating parts.

Peelable shims are typically made from a stack of thin metal foils that are bonded together with an adhesive. The thickness of the shim can be adjusted by peeling off layers of foil until the desired thickness is achieved. This can be done quickly and easily with a sharp tool or even by hand.

Peelable shims are available in a variety of materials, including aluminum, stainless steel, brass, and carbon steel. They are also available in a variety of sizes and shapes.

Peelable shims are used in a variety of industries, including:

Shree Ambica Gaskets Pvt. Ltd.

Shree Ambica Gaskets Pvt. Ltd.